ABOUT

NEXT GENERATION FILTER COMING

Guaranteeing Food Safety - PACIFIC TECHNO FILTER (PTF) -

Demand for maintaining food safety for consumers is increasing on a yearly basis, and food suppliers that fail to respond to the demand are at risk of severely damaging their reputations. In other words, companies that have made improvements and implemented efforts to maintain safely as part of their corporate philosophy will be highly acclaimed. Of all the many machines used in the various manufacturing processes as food chain from the production of raw ingredients to the dinner table, strainers are used to prevent one of the biggest threats that foreign matters mix into food. Here we will introduce the PACIFIC TECHNO FILTER (PTF), which is used by many food suppliers.

PACIFIC TECHNO FILTER In-Line Strainers are certified 3A Sanitary standards.

Certificate 3481 / 42-02

The certificate holder is our subsidiary company Pacific Special Alloy Castings Co.,Ltd.

View certificate

Strong points

Durability

Extended life expectancy with high material properties in terms of thickness, corrosion-resistance and strength.

Sanitation

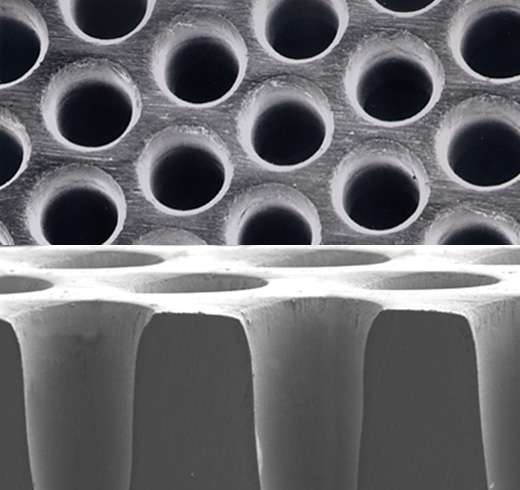

Tapered hole edges facilitate washability and keep functionality without clogging.

Improved Performance

Thick plate and fine holes can lead to unnecessity of buck-up materials and reduce pressure losses.

Workability

The weight is light and the size can be compact.

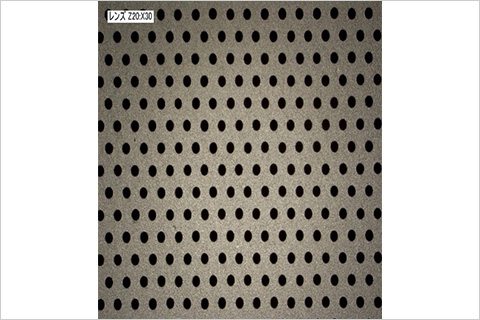

HOLE PROPERTIES

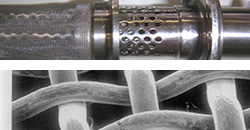

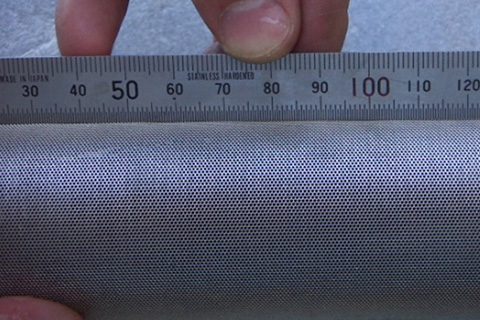

Surface and Cross Section of Our Filter Elements

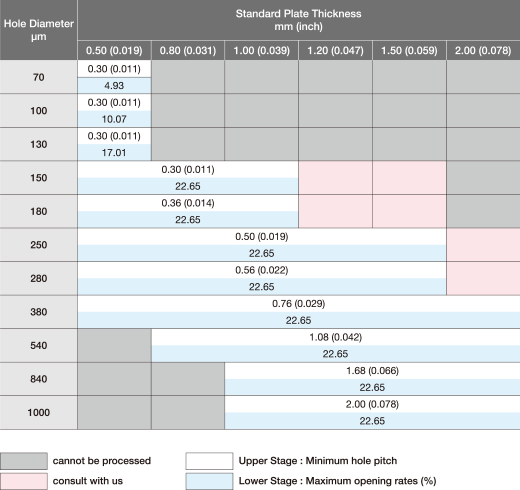

Hole Diameters and Plate Thicknesses

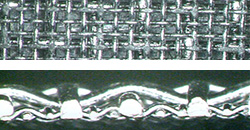

lssues With Conventional Filter Elements

| Type | Element Characteristics | Filter Structure | Issues |

|---|---|---|---|

| Wedge Wire |  |

Triangular edges running along a frame wrapped in wire. |

|

| Wire mesh |  |

Overlapped wire mesh outside or inside surface of the cylindrical punching plate. |

|

| Sintered wire mesh |  |

Diffusion bonded wire mesh for multiple layers. |

|

TECHNICAL DATA

-

WashingTest

-

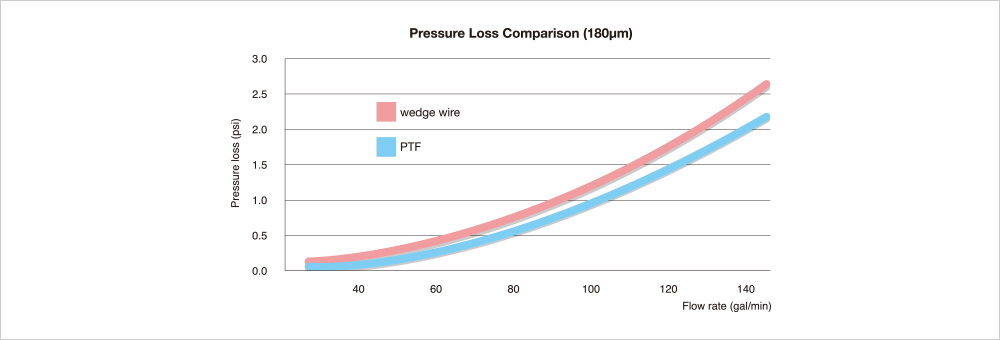

Pressure Loss Test

-

Filtration Test

-

Broken Test

-

Pressure Test

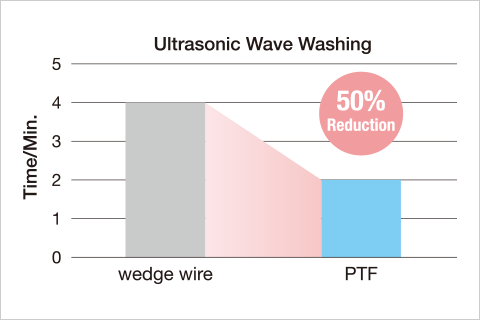

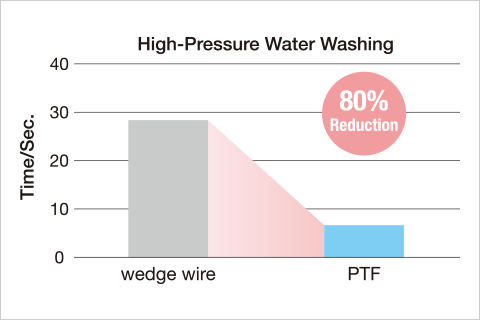

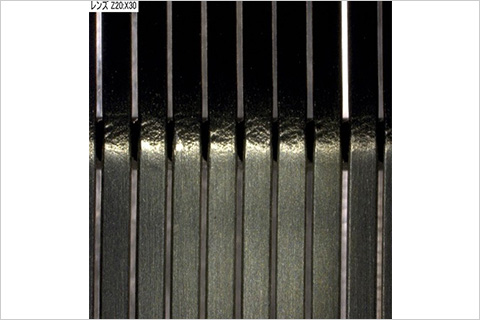

A wedge wire and PACIFIC TECHNO FILTER (PTF) were coated in yogurt and then have washed by high-pressure water and ultrasonic waves. The results are shown below.

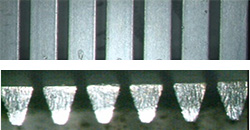

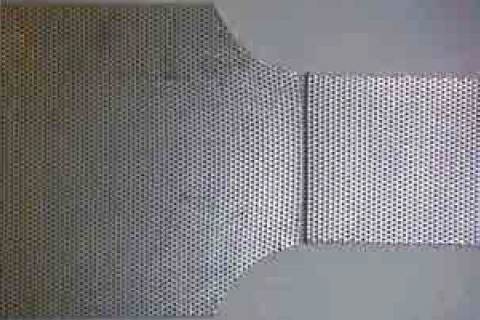

Surface After Ultrasonic Wave Washing

Residual detergent was observed on the reinforcement areas of the wedge wire, on the other hand, the simple structure of the PTF allowed washability to be completed within two minutes.

Washing performance on PTFs is far superior to that on wedge wire filters. In particular, excellent results can be achleved In less time in the high-pressure water washing. Also, ultrasonic wave washing can be effective in many food production plants.

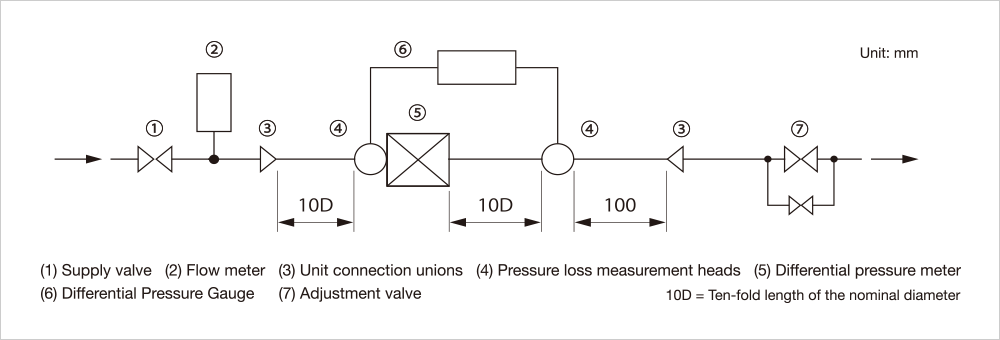

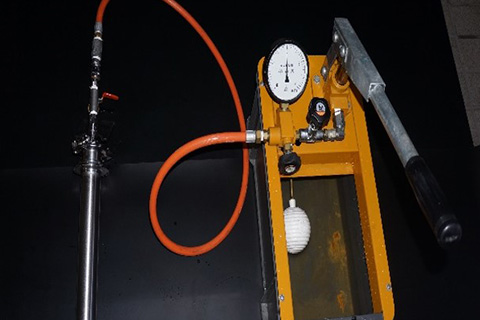

Strainer pressure loss is calculated in accordance with loss of hydraulic tests on water supply equipment (valves) stipulated by the Japan Water Works Association.

The test apparatus consists of the components shown in the illustration below. Pressure differences, which have to be over 21.8 psi flow pressure, are measured before and after the apparatus that controls each flow volume.

(Standard : JWWA B 108:2004)

Pressure Loss Test Apparatus Configuration

wedge wire

PTF

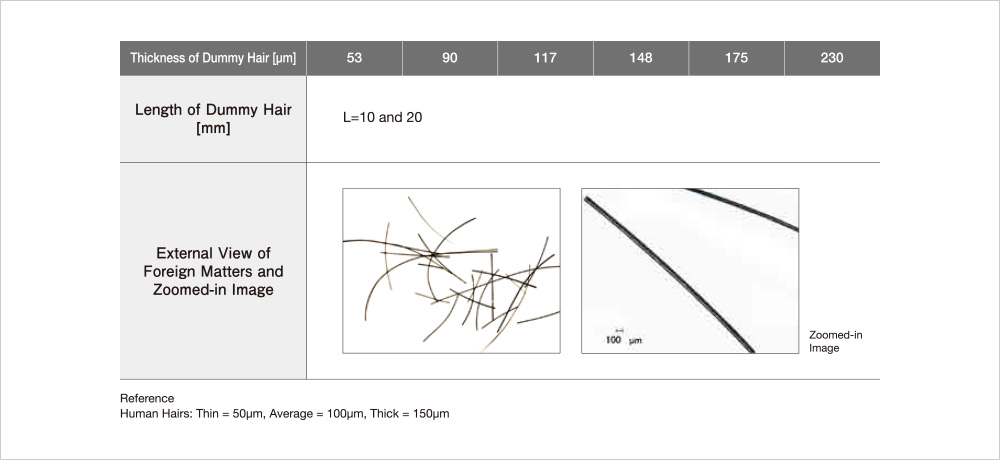

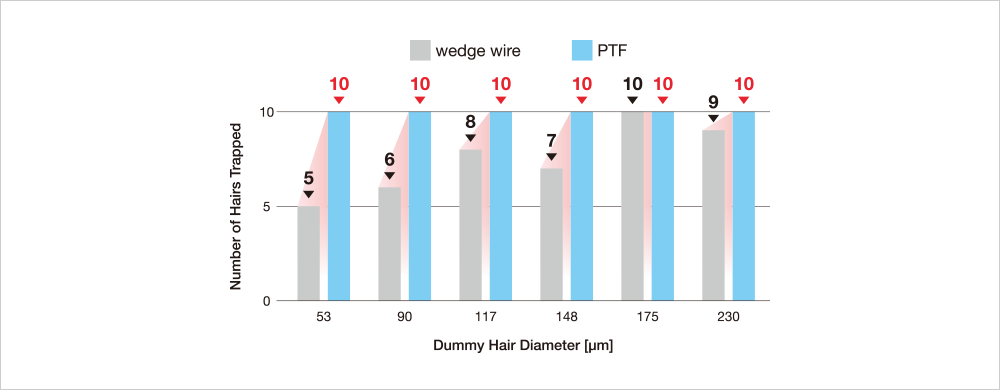

Ten pieces of filament-shaped foreign matters (thickness 53 to 230μm × length 10 and 20mm) were passed through PTF and wedge wire with 180μm hole diameters. The number trapped by the filter counted.

Tension Tester

Broken Element Shape/Maximum Tensile Load: 1214 lbf (5.4KN)

Mesh : 380μm × P760μm

With the rubber tube set in place

Rubber tube set into the inside of the filter and water pressure applied

Testing in progress

Load of 290psi (2MPa)

Deformation checked (no deformation)

PROJECT

DELIVERY RECORD MORE THAN 6,500 ITEMS.

Examples of the Use Processes

- - Raw material delivery process

- - Melting powdered material and extraction process

- - Pasteurization and filling process

- - CIP line

Applicable Products

Delivery record more than 6,500 items.

・Milk, cheese, butter, margarine ・Yogurt ・Mayonnaise ・Edible oil

・Carbonated beverages ・Fruit juice beverages・Tea

・Food additives ・Sauce ・Ice cream

・Chocolate ・Soup・Shochu white spirit ・ Other foodstuffs

CLICK HERE

TO DOWNLOAD

THE BROCHURE