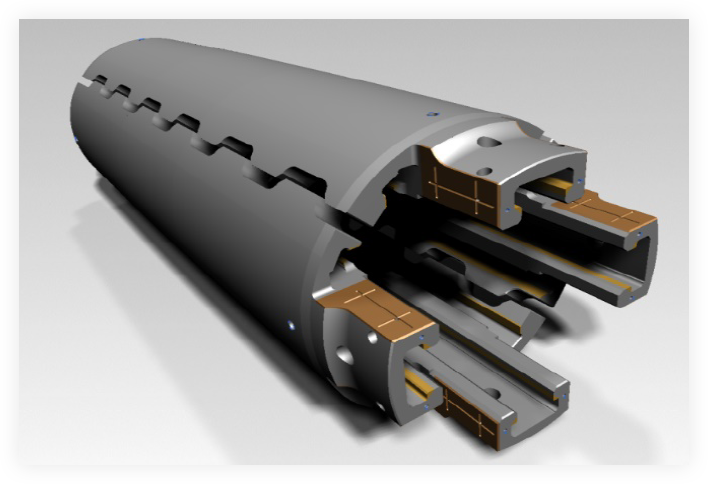

ABOUT

SPECIAL MATERIAL YST 5

High-Temp Durability

Durability against high-temperature brittleness

When winding condition is bellow 750℃, the excellent toughness characteristics of YST5 will be kept. When it is exposed for long time under the tempering temperature to 780℃ (or more), toughness characteristics of YST5 will be decreased. However, the surface crack growth as observed in YST5 is very slow, it does not cause sudden breakages of segments.

Low-Temp Durability

Durability against Low-temperature brittleness

Even if it is exposed to the embrittlement temperature range of 450 to 500℃ for long time, embrittlement which is observed in the case of high Cr steel does not occur in YST5.

Abrasivity

Good abrasion resisting property

Even in the condition of high temperature, YST5 has good abrasion resisting property.

Re-machinablity

Good re-machinability

Good re-machinability can be discovered when reusing YST5 segments.

Compatibility

High performance and cost benefit

In addition to high performance, YST5 has cost benefit as well. Alloy components of YST5 is fewer than the 12Cr based material (ex.GX22CrMoV12-1).

COMPARISON WITH GX22CrMoV12-1

As properties like heat resistance, abrasion and corrosion resistance, GX22CrMoV12-1 is widely adopted in heavy industrial market (Hydraulic, Gas&Steam turbine, etc). Unlike these markets, however,hot-rolled mandrel equipment in steel market requires special materials that can be used under repetitive conditions of heating and cooling for many times. The such harsh conditions causes a lot of heat cracks on surfaces of segments of mandrels. In order to avoid breakages and crack growth from surfaces of segments to deep inside, the material of segments must be given top priority with sufficient fracture toughness properties which make the progress of cracks delay. This point is the most important property to eliminate the sudden stop of facilities. YST5 has the property, therefore it is the most suitable material for hot-rolled mandrel.

Example of cracks in GX22CrMoV12-1

| Material | YST 5 | GX22CrMoV12-1 |

|---|---|---|

| Proof stress (N/mm2) | 560/GOOD | 600/EXCELLENT |

| Tensile strength (N/mm2) | 710/GOOD | 785/EXCELLENT |

| Elongation (%) | 22/EXCELLENT | 18/GOOD |

| Reduction of area(%) | 70/EXCELLENT | 48/GOOD |

| Hardness (HS) | 33/GOOD | 40/EXCELLENT |

| Charpy absorbed energy(J) Temp.20°c | 115/EXCELLENT | 25/NO GOOD |

YST 5 WINDING SURFACE STATUS

After winding 1,200,000 tons(still usable/stock for emergency)

HONEYCOMB PATTERN as a feature of YST5 appears on surfaces.

It is very shallow and NEVER progresses to Harmful cracks.

After winding 1,500,000 tons

In some mills, the same amount of coils are able to

be wound further by re-machining the surface after use.

Supply List(number of annual)

| Year/Customer | 2000 | 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2000~Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N S Corp | 8 | 3 | 2 | 15 | 15 | 6 | 8 | 6 | 16 | 8 | 10 | 9 | 10 | - | - | - | - | - | - | - | - | 114 |

| SM Industries | 2 | 3 | - | 1 | 1 | 1 | 4 | 5 | 2 | 2 | 1 | 1 | 1 | - | - | - | - | - | - | - | - | 24 |

| N&S Metal | - | - | - | - | - | - | - | - | - | - | - | - | - | 13 | 13 | 15 | 13 | 9 | 18 | 20 | 10 | 81 |

| N.K.K. | 4 | 4 | 8 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 14 |

| KW Steel | 2 | 4 | 3 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 9 |

| J Steel | - | - | - | 8 | 8 | 4 | 12 | 9 | 9 | 5 | 6 | 5 | 5 | 4 | 5 | 8 | 12 | 10 | 9 | 11 | 11 | 119 |

| K Steel | - | 2 | - | 1 | 1 | - | 3 | 6 | 1 | 1 | - | 1 | - | 2 | 1 | 3 | 1 | 2 | 1 | 2 | 1 | 29 |

| N Steel | 6 | 5 | 3 | 1 | 1 | 1 | 5 | 5 | 3 | 4 | 1 | 3 | 4 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 2 | 62 |

| N M Industry | - | - | - | 1 | 1 | - | - | 1 | - | - | - | - | - | - | - | - | - | - | - | - | - | 3 |

| T Steel | - | - | 2 | - | - | - | - | 2 | 2 | - | - | 1 | - | - | 1 | - | 1 | - | 3 | 2 | 2 | 16 |

| NK Steel | - | - | - | - | - | - | 1 | - | - | - | - | - | - | - | - | - | - | 1 | - | - | - | 2 |

| I Industry | - | 3 | 2 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 5 |

| M Group (for US) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 1 | - | - | - | - | - | 1 |

| Total | 20 | 24 | 18 | 27 | 27 | 12 | 33 | 34 | 33 | 20 | 18 | 20 | 20 | 21 | 22 | 29 | 30 | 25 | 34 | 38 | 26 | 479 |

CLICK HERE

TO DOWNLOAD

THE BROCHURE