OUR GOALS

TROUBLE AND RISK

- Fallling risk which casuses stop operation

- Short life which leads costs to not only replace thimbles but also install scaffolds many times.

OUR GOALS

- Stable operation

- Cost reduction

We have been comitted to Japanese cement industry for several decades and accumulating much more experiences. Most of Japanese cement companies have been using not only coal and natural gas but also tires, plastics, waste wood and waste oil as fuel. Therefore, the corrosive condition of cyclones of preheater have been becoming harsher and harsher. In order to meet the severe environment, we have developed proper materials. In addition, we are dedicated to life assessment of thimbels during outage periodically so that we could reduce risks of severe accident like falling and collapse of thimble segments. We have been devoting ourself to customer's stable operation and cost reduction.

FIRST OUR SOLUTION

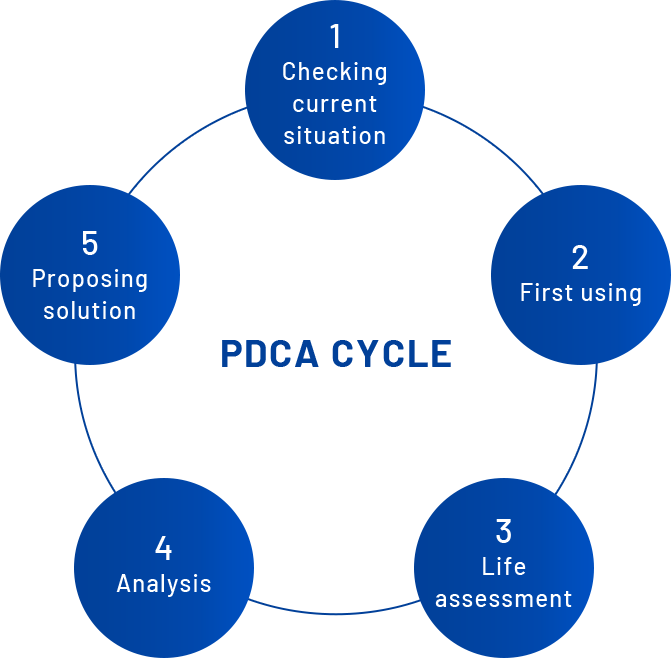

REPETITIVE POSITIVE CYCLE

Our activity is based on " Repetitive positive cycle" which is to pursue the best solution for our customers. We strongly believe that not only just proposing materials but also checking on site is the best solusion.

Step 1 Checking current situation

We clarify current problems in your plant.

Step 2 First using our products

Based on your status, we choose proper materials for you and suggest the try.

Step 3 Life assessment on site

We check thimbles on site in order to reduce risk of collapse of thimbles.

Step 4 Analyzing thimbles

We analyze cause of corrosion of used products in our facility.

Step 5 Proposing the best way

Based on analysis, we propose the best way to meet your plant.

SECOND OUR SOLUTION

SPECIAL MATERIALS AND FLEXIBLE OPTIONS

We have special materials for each cyclone environment as well as flexible options. These materials and options have been developed based on accmulated knowledge since we have dedicated in cement industry for decades.

Flexible options

| Length | Thickness | Weight |

|---|---|---|

| 760 mm | 20 mm | 46 kg |

| 16 mm | 37 kg | |

| 660 mm | 20 mm | 41 kg |

| 16 mm | 33.5 kg |

| Name | Chemical composition (%) | Tensile Strength (N/mm2) | Elongation (%) | Tensile strength under high temperature (N/mm2) | ||||

|---|---|---|---|---|---|---|---|---|

| C | Cr | Ni | Others | 800 ℃ | 1000 ℃ | |||

| HB508 | 0.2 - 0.4 |

18.0 - 23.0 |

8.0 - 12.0 |

Incl. | ≧490 | ≧23 | ≧195 | ≧45 |

| HB512 | 0.2 - 0.4 |

24.0 - 28.0 |

11.0 - 14.0 |

- | ≧490 | ≧8 | ≧195 | ≧45 |

| HB515L | 0.08 - 0.15 |

22 - 25 |

14.5 - 16 |

Incl. | ≧440 | ≧8 | ≧145 | ≧45 |

| HB525D | 0.25 - 0.35 |

23 - 25 |

23 - 25 |

Incl. | ≧490 | ≧8 | ≧195 | ≧75 |

| PH35 | 0.35 - 0.75 |

24 - 27 |

33 - 37 |

Incl. | ≧440 | ≧5 | ≧245 | ≧75 |

Delivery record

| Delivery record ( Numbers of sets) |

Life time (Average) |

|

|---|---|---|

| Stage1 (Bottom Stage) | 227 | 1.5 to 4 years |

| Stage2 | 78 | 4 to 5 years |

| Stage3 | 60 | 8 to 10 years |

BENEFITS

1. REPLACEMENT FROM CAGE OF STEEL PLATES

Problems

- a) It takes much cost to replace cages. In order to bring some pieces of cages, it is necessary to dismantle cyclones. So, renting heavy machineries is required.

- b) Due to the structure of cages, stress of cages stays inside themselves. Threfore, it is necessary to repair distorted cages after every shutdown.

- c) Materials for cages under high temperature are limited. It can be considered that lifespan of cages is shorter than steel casting segments which are developed for heat resistance.

Benefits

- a) Our segments can be carried in cyclones through windows. It is easier to install thimbls segments than cages. It leads cost reduction and more safety work.

- b) Our thimbles segments are split type which relives stress easier. Therefore, repairing thimble segments during outage is not needed.

- c) Our materials are suitable for each cyclone stage. It is expected to have longer life than cage.

2. REPLACEMENT FROM OTHER SPLIT SEGMENTS

Benefits

- a) Our segments can be installed by various options. It is available to set just one row or one piece to meet each condition. Long life and proper life of thimble segements can be expected. In other words, number of times to replace thimble segments and install scaffolds would be able to be cut. As the result, the cost reduction of replacement and installation would be expected.

- b) Through "Repetitive positive cycle", we can find out the best solution for each customer even environment is changed and time is passed. We pursue not only expecting long life of thimble segments but also caring about the risk of collapse of thimble segments through on-site assessment.