Mixers and Sieves (Pacific Machinery & Engineering)

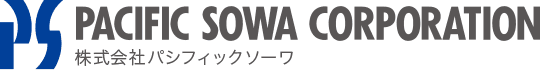

Pam Apex Mixer WB Model/WA Model

-

- Scope of Application:

- Mixing Tank Capacity 3 L - 25000 L

-

- Main Applications:

- Mixing, dispersion, fiber dissolution, humidification, granulation, drying, reaction, and others

- ● High-quality products can be manufactured in a short amount of time thanks to floating diffusion mixing using shovel blades and high-speed shear dispersion by high-speed rotating chopper blades

- ● It is also possible to mix powders with different mixing ratios and specific gravities.

- ● The blade shape and material can also be selected to be in line with the raw material

- ● We can also manufacture small tabletop sizes that are ideal for testing and research

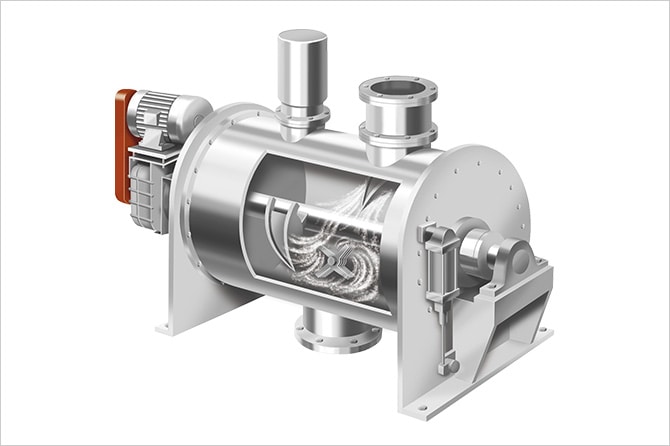

Cone Mixer HF Model/HFL Model

-

- Scope of Application:

- Mixing Tank Capacity 50 L - 3000 L

-

- Main Applications:

- Mixing, kneading, granulating, dispersing, coating

- ● Supports a wide range of applications including mixing, kneading, granulating and dispersing

- ● Supports jacket structures and liquid additives

- ● Mixes Fiber-reinforced mortar and concrete that cannot be kneaded in conventional mixers

- ● High discharge performance using a cone-type mixing tank

- ● We can manufacture using materials that are suitable for mixing raw materials (SS, SUS304, 316, and others)

Spiral and Pin Mixer W Model/D Model

-

- Scope of Application:

- 250 L/Hr to 30000 L/Hr

-

- Main Applications:

- Dissolving, kneading, humidifying, mixing

- ● Enables continuous dissolution, kneading and humidification of powders and fluids

- ● By disposing a mechanism to allow the material to remain in the mixing tank for a fixed period of time, it is possible to prevent shortpass reduction, which was a disadvantage of conventional continuous mixers, and to perform uniform and high-precision processing.

Vibrating screen: SEU Model and ML Model

-

- Scope of Application:

- SEU Model 0.5-10 mm ML Model 0.15-25 mm

-

- Main Applications:

- Environmentally friendly oscillating sieve for mining, ceramic engineering, fertilizer, feed, foods and chemicals offering low noise and easy maintenance

- ● Supports with options such as our unique clogging prevention system and dust-proof type.

- ● Solid liquid classification and wash and dehydration series are also available

- ● Multi-stage net greatly improves processing capacity (ML type)

- ● You can select the net tensioning method and open the mesh to prevent clogging