Agitator(Shimazaki Mixing Engineering)

We will select the optimal mixer considering its application and properties of liquids to be used for mixing all kinds of materials. Furthermore, this can be used in a variety of applications, from small machines to large ones, from low pressures to high pressures, from low viscosities to high viscosities, and to manufacture using special materials.

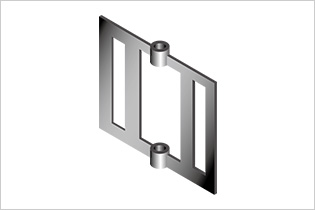

Forward and reverse-rotating agitator

The mixing shaft is inverted every 90° instead of rotating in a single direction

-

- Manufacturing Scope:

- 0.2 kw to 110 kw

-

- Main Applications:

- Dissolving, reaction, temperature uniformity, dispersion, prevention of sedimentation.

- ● The liquid level can be kept flat during mixing, reducing the mixing in of air bubbles

- ● Ideal for stirring with high viscosity materials such as rubber, adhesives and resins etc.

- ● Tank is easy-to-wash after mixing because mixing is possible without a baffle.

Forward and reverse-rotating liquid continuous extraction tower

Does not stir using a unidirectional action. Adopts a reciprocating rotational motion thereby increasing contact efficiency.

The extraction tower efficiency is three times that of the conventional efficiency. Extracts even trace active ingredients that have been given up on until now.

-

- Manufacturing Scope:

- φ74×691H - φ1700×18350H

-

- Main Applications:

- Liquid - Liquid Extraction

- ● Contact efficiency increased dramatically thanks to reciprocating rotation

- ● Compact compared to conventional equipment thanks to high extraction efficiency

- ● The porous plate is inverted so liquid emulsion is prevented.

Jet Type Agitator

The mixing shaft which is equipped with special blades rotates at a high speed, generating a strong discharge flow

-

- Manufacturing Scope:

- 0.4 kw to 15 kw

-

- Main Applications:

- Mixing, uniform mixing, uniform temperature, prevention of precipitation

- ● Ideal for mixing low-viscosity liquids to produce a strong discharge stream

- ● The liquid level can be kept flat during mixing, reducing the mixing in of air bubbles

- ● Tank is easy-to-wash after mixing because mixing is possible without disturbing plate.

Rotary Type Agitator

Mixer allowing selections of blade shapes and speeds suitable for mixing purposes and substances

-

- Manufacturing Scope:

- 0.2 kw to 350 kw

-

- Main Applications:

- Can be used for any purpose depending on the type of blades

- ● Wetted parts support special materials and various linings

- ● Allows selections of various seals, such as mechanical seals for the shaft seal

- ● Compatible with height limits, and the like

Types of blade according to the mixing objective

◆ Blades for high speeds (mainly high-shear action)

Mixing Objective: Dispersion, emulsification, mixing, and others

-

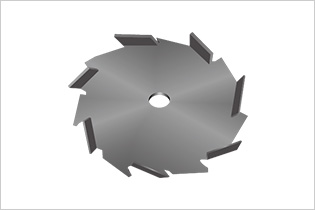

Edge Turbine Blade

-

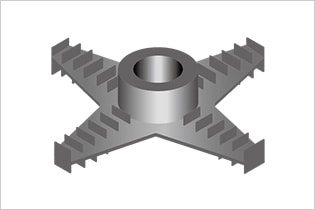

Homogenous Blades

-

Edge Paddle Blades

-

Jet Blades

◆ Blades for mid-speeds (mainly for discharge and shear action)

Mixing Objective: Mixing, reaction, dissolution, crystallization, washing, neutralization, prevention of precipitation, and others

-

Allard Blades

-

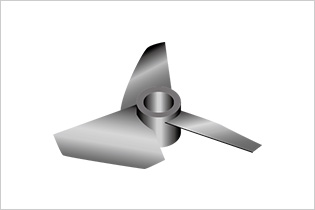

Propeller Blades

-

Pitched Paddle Blades

-

Paddle Blades

-

Turbine Blades

-

Pitched Turbine Blade

-

Bent Turbine Blade

◆ Blades for low-speeds (mainly for discharge action)

Mixing Objective: High viscosity, highly concentrated solution mixing, dissolution, and others

-

Gate Blades

-

Ribbon Blades

-

Anchor Blades